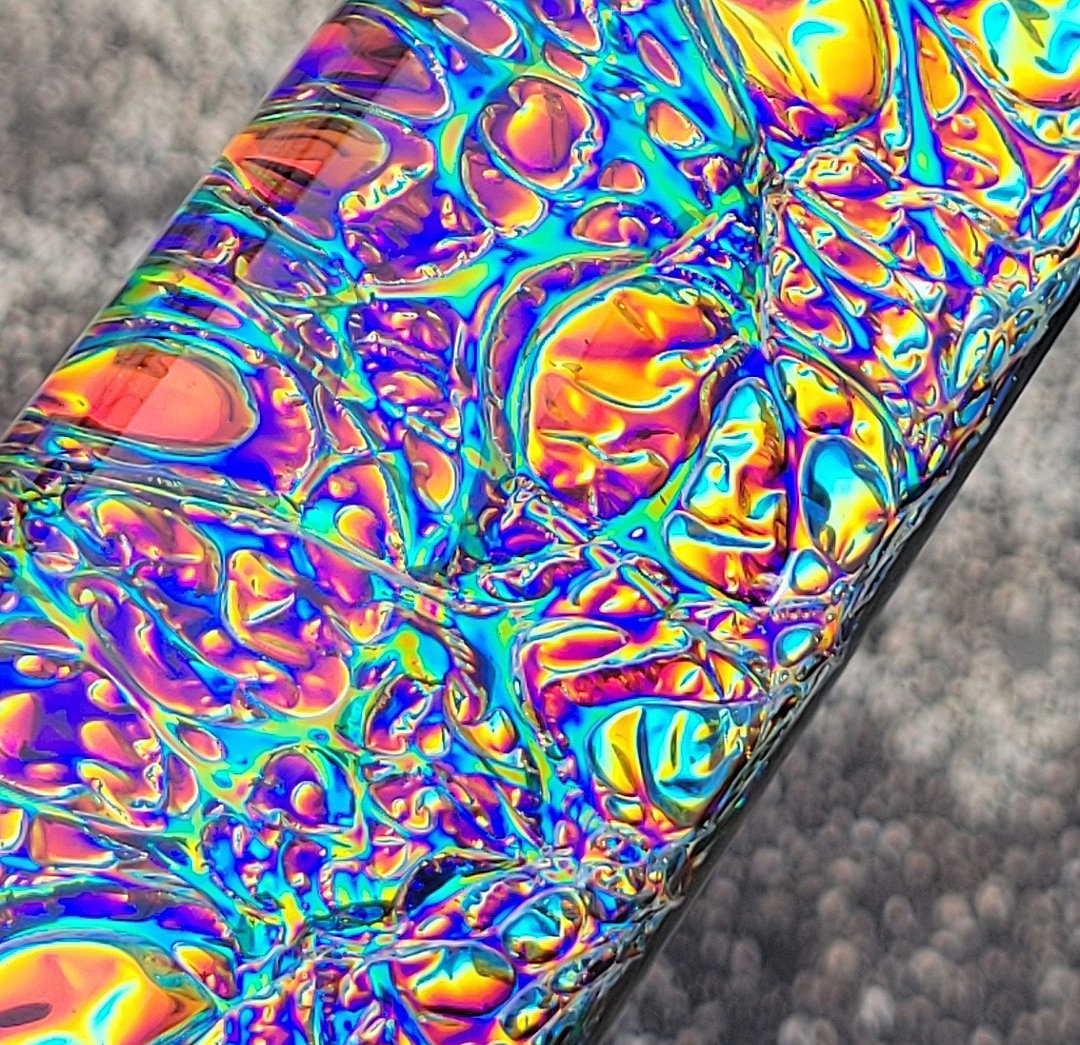

Burl Textures

Red Burl Knife

What makes Dichrolam® Burl Textures so amazing?

The dichroic film “optical core” is the most color saturated synthetic material in the world due to the “structural color” of its multilayered makeup. This core filters light wave phases, resulting in breathtaking colors with no dyes or pigments or any kind.

Additionally, literal 3-dimensional topography under the flat resin surface provides visually unique depth and lensing. The patterning of this topography is executed by hand for every single piece, so you will never see two Dichrolam Burl Textures that are the same!

So many opal prospectors have dreamed of mining monstrous veins of Black Fire Opal from Lighting Ridge Australia and extracting it intact to make huge tabletops or unlimited pieces for a line of fine jewelry. How amazing would THAT be?!?!

It is right here, right now, since Dichrolam Burls are optically identical to Opal, but engineered for easy fabrication into real world, high value items.

Our core line of Dichrolam Burls started with Black Sea and Red Burl, and has expanded to include Fire Burl, Titanium Burl, Dragon Burl, Caribbean Burl, and Dragon Burl in Pearl. Have custom needs? We have tested numerous other color combinations, pattern intensities, and lamination methods. We’re happy to work with you to plan and quote your large-scale custom orders (min x square feet?). Contact our manufacturing center for more information.

Dichrolam Burls are produced in four main stock categories: solid resin stock, “prelam” thin stock, resin receptive heavy stock, and glass stock. Other laminate options are available for custom orders.

Fire Burl Resin Stock

Solid Resin stock - This version features the textured dichroic core in medium to low height topography with very hard resin on both sides of the dichroic core. The top is a clear, high durometer (95+) resin that has proven durability and scratch resistance after buffing. The backing is usually black but can be clear or white.

This version is not produced with a finished surface, and is often surfaced to spec thickness by the creator of the product. This stock is generally made into products like knife handles where it will be shaped, sanded and polished.

Thickness range is .060" to 1" with special resins, but is usually stocked in 3/16" thick.

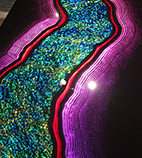

Glass stock - Any of the burls can be laminated to the back surface of glass with proprietary polymers. Glass stock is great for table tops or architectural surfacing.

All options available from polished edges, holes, tempered and Low Iron glass to mountable backing plates in cement board for fastening to substrates.

Thickness range depends primarily on glass preference.

Fire Burl Prelam Stock

"Prelam" stock - This version is engineered for thin inlay use with tight radius bending capability, primarily for ring and pen makers. But it is also great for general inlay use, inlay use in poured epoxy tabletops and even wall coverings. The textured dichroic core has low height topography for thickness of about .025" with the surface treated for seamless adhesion of customer applied resins. The back of the dichroic core is a flexible elastomer resin with a high adhesion PSA film applied for easy bonding to substrates.

Prelam stock is easily cut with razor to fit into product cavities and is supplied with a masking film on top to keep it clean while handling (this must be peeled off prior to resin fill).

Resin Receptive stock - Similar to thin "Prelam" stock, but this version is Resin Receptive. The burls are heavily textured, without the costly flattening process and without the adhesive backing.

At nearly 1/8" thick, Resin Receptive films are designed primarily for river tables, inlays and resin art where end user applies epoxy directly to the adhesion treated surface. Resin Receptive films can be coated with conventional clear coats to be used for wall covering or any decorative surfacing without epoxy filling.

Thickness range starts at roughly 1/8" thick.

In addition to our four categories of stock Burls, we can also accommodate requests for ARPET stock and other Glass/Acrylic stock on custom orders.

Ready to start working with Dichrolam?

We have fabrication guides available for download: (coming soon!)

Be sure to visit our Dichro Gallery for examples of the amazing products that have been created with Dichrolam Burl Textures.

Looking to purchase Dichrolam Burl Textures?

We have several retail distributors:

MakerMaterialSupply.com

RingSupplies.com

And for our new Resin Receptive Burl films:

Domestic - Direct Sales starting at 4 sq. feet

Internationally - HealthofMindArt.com of Australia

Feel free to reach out to our manufacturing center directly! We quote custom work starting in the low 4 figures and can build a composite product around your specifications. If you can dream it, John and his team can fabricate it!

Feel free to reach out to our manufacturing center directly! We quote custom work starting in the low 4 figures and can build a composite product around your specifications. If you can dream it, John and his team can fabricate it!

Please contact our national rep Igor Beaufils at IgorGlass.com. Igor has years of experience with our products, as well as commercial glass, and can help you make an informed decision based on your specific project needs.

Please contact our national rep Igor Beaufils at IgorGlass.com. Igor has years of experience with our products, as well as commercial glass, and can help you make an informed decision based on your specific project needs.

Dichrolam Burl Sample Packs

We currently have sample packs available for purchase for our Burl Lines. These may include Resin stock and Prelam stock in a number of Burl Textures and color combinations.

If you'd like to order samples please fill out this form and indicate your preferred Burl Textures!

Black Sea

First patterned in 1999, this burl texture uses "blue" dichroic film. It is defined by its dominant deep blues and greens, interspersed with orange and red veins. Black Sea is a challenge to control in regard to the pattern and color concentrations. So, as with real wood, there is variation - some areas have tight "cells" with red streaks, and some are wavy blue and green.

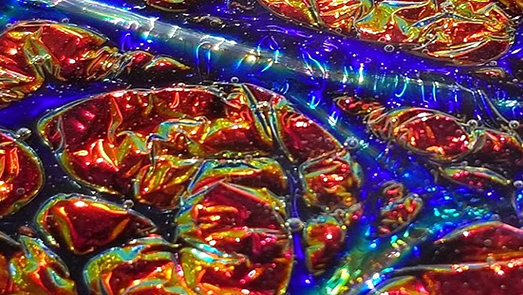

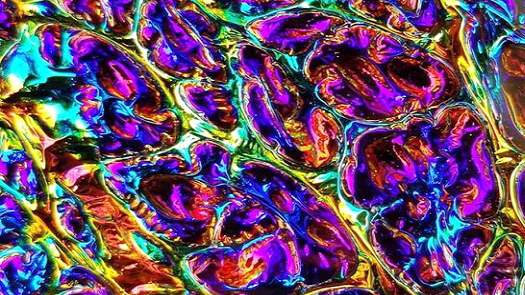

Red Burl

Early versions, starting around 2005, lacked the blue/violet streaks between the red "coral heads", but now

you can expect copper red dominance with blue/violet veins and occasional bright blue "ice" veins. Red burl has

high color/pattern consistency throughout every square foot but takes 2X longer to pattern than Black Sea.

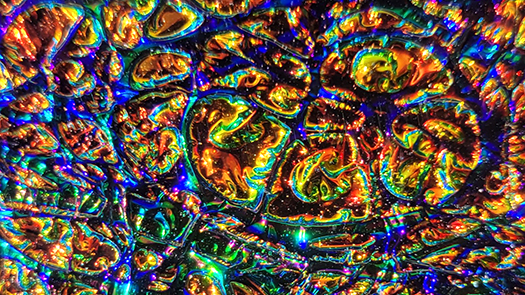

Fire Burl

In short, our Fire Burl contains every color of the rainbow. Several dominant colors can be achieved with various patterning steps, but the most captivating is the "purple-ized" version which yields lime green veins within deep magenta/purple. Then blend in lots of red, yellow, blue etc. Fire Burl can be counted on for greater than 85% consistency across every square foot.

Titanium Burl

This texture, named for its similarity to the intense coloration of Titanium metal oxides, features regal gold dominant colors with sky blue and magenta streaks. Based on a raw film that was destined for a supplier's scrap pile, this burl is the most unlikely of fabrications and why we consider it as coveted as Gibeon Meteorite.

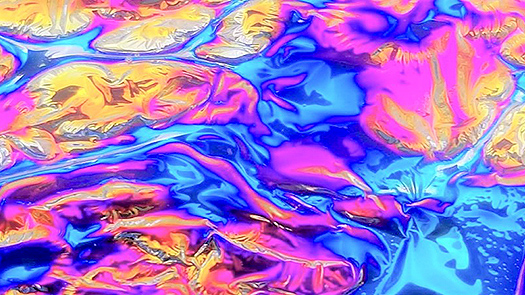

Caribbean Burl

South Beach colors of Coral and Teal in Caribbean Burl come from the transmitted coloration THROUGH the dichroic core film due to white backing. Pastel colors in this would have been great in jewelry on the set of Miami Vice or a salon table in your yacht.

Dragon Burl

Highly colorful like Fire Burl above, but lighter, green/gold shade overall. Expect the same purple, red, violet and lime green veining, but interspersed with gold heads that di-chromatically shifts into green at skewed viewing angle.

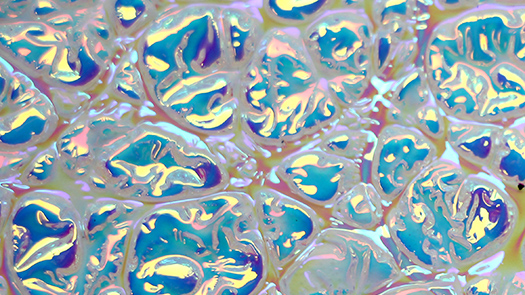

Dragon Burl in Pearl

Dragon Burl film but with a white pearl backer. The transmitted coloration under the gold heads shows up as blue points interspersed with white rivers glinting with purple, red, violet and lime green.